RENISHAW, a leader in the production of metal additive manufacturing systems, has supplied two of its RenAM 500M systems to Madit Metal this month, a Basque start-up company based in Zamudio (Bizkaia). Madit was created to offer services to the industry based on its knowledge and experience in metal 3D printing using PBLF (Powder Bed Laser Fusion) technology. Madit services includes consulting, design and manufacturing of metallic parts.

Its associates have more than 6 years of experience working with this technology applied to the aerospace sector, where they have achieved great advances and more than 15 years of experience in the design and manufacturing of metallic products.

After investing in RENISHAW’s RenAM 500M systems, Madit Metal will use all tools, software packages and hardware to propose end-to-end solutions that encompass design and production, optimizing results and ensuring full process control. Also, they will take an industrial and high productivity approach to PBLF technology, including the optimal facilities to perform all the post-processes the customers need.

RENISHAW additive manufacturing systems melt layers of powder by laser, from fine powder particles within an inert atmosphere and ensuring a high-quality manufacturing environment, producing complex shapes that cannot be replicated or created by conventional systems.

The 2 RenAM 500Ms installed feature an ultrasonic powder recirculation system to minimize contact with powder, improve productivity and reduce the risk of cross-contamination. They also have monitoring and process control systems managed through InfiniAM Central, as well as the latest component quality control systems through camera and thermographic analysis offered by InfiniAM Spectral.

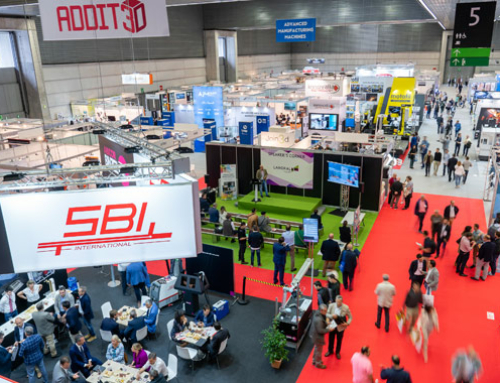

“As for the sectors that will lead our activity, our intention is to address the metal-mechanical industry and product design sectors, covering all types of metal parts except those in the medical sector,” their associates say during the launch of Renishaw’s RenAM 500M systems at their facility.

One of the last collaborations that we can emphasize from Madit has been with the Moto Team of the School of Engineering of the University of Deusto (UDMT) where they have manufactured stainless steel parts (SS316L) for the new bike that will be used in the international university championship Smart Moto Challenge.

Madit has opted for RENISHAW systems thanks to the experience gained in recent years with them. ‘The technological capabilities of the machines, as well as the monitoring and process control systems. In addition, having a headquarters in Spain further improves the relationship between the parties’, indicates from the company.

The use of industrial metal additive manufacturing will enable Madit to offer its customers services unthinkable with conventional technologies, as well as benefit small-scale manufacturers with a customization service due to the design freedom.

Through 3D printing it is possible to reduce manufacturing times, reduce the unit cost of parts by eliminating non-recurring costs and obtaining products of high quality and functionality.

Source: Addimat

Leave A Comment