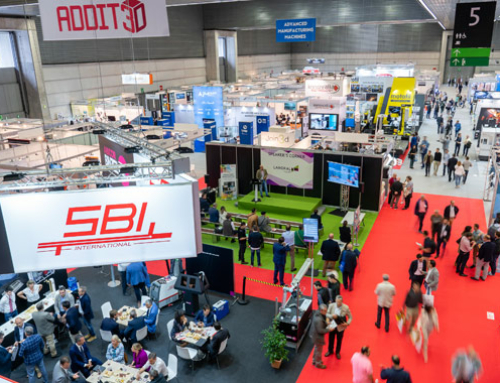

This year’s BIEMH exhibition (28th May-1st June, Bilbao Exhibition Centre) will see Stratasys, a global leader in additive technologies, showcase its latest 3D printing solutions in conjunction with Spanish resellers, Pixel Sistemas (Stand B-33, Pavilion 4) and Comher (Stand C-18, Pavilion 2). Stratasys will demonstrate the versatility of its FDM and PolyJet 3D printing technologies for a wide range of applications across the entire product development process – from fully-functional prototypes, to manufacturing tooling and final production parts.

Accelerating Product Design

Among the line-up of Stratasys 3D printing solutions on exhibition will be the F370 3D Printer, from Stratasys’ widely-acclaimed F123 Series, which received a staggering 1000 orders in its first 6 months following commercialization. The F123 is the ideal solution for every prototyping stage, from concept verification and design validation to functional testing, as it continues to be a hit among design groups.

Also running live will be the world’s only full-color, multi-material 3D printer, the Stratasys J750. With the unique ability to produce full color parts in multiple materials – in a single print – the J750 3D Printer eliminates several important design processes. This enables product designers to make significant time-savings during prototyping and the luxury of near instantaneous decision-making to accelerate product development.

The show will also mark the Spanish debut of Stratasys’ vivid colors solution. Available on the Connex3, J750 and J735 3D Printers, the new package offers in excess of 500,000 color combinations, enabling designers and manufacturers to achieve highly accurate color matching, and advanced clear parts with texture functionality.

Enhancing Traditional Production with Additive Manufacturing

Visitors will learn how additive manufacturing can add value when replacing traditional manufacturing applications – from the optimization of tooling processes, such as high-temperature composite applications, to the significant savings achievable during the production of manufacturing tools like jigs and fixtures.

This is exemplified by Seville-based aerospace manufacturer, Indaero, a major Airbus supplier, who is deploying Stratasys FDM additive manufacturing to enhance its tooling process, enabling the company to extend its offering into lightweight, complex tools that cannot be produced with traditional manufacturing. Visitors will learn how, using the Stratasys Fortus 450mc Production 3D Printer, led to production tools being produced 66% faster, 75% lighter and at 50% of the cost compared to traditional manufacturing methods.

The effective use of the technology for final part production will also be an important focus at BIEMH. For companies interested in the potential of using high-performance thermosplastics to replace heavy, and often expensive metal components, visitors can see the impressive capabilities of Stratasys’ unique FDM Nylon 12CF material – the industry’s first FDM composite 3D printing material. This thermoplastic contains 35% chopped carbon-fiber and is strong enough to replace metal, allowing designers to develop more practical and functional designs.

Similarly, parts created using the new PEKK-based high-performance thermoplastic, Antero™ 800NA, will also be presented at the show. Visitors will be able to see the significant advantages offered by the material, including the ability to produce lighter-weight parts, reduce inventories, and improve profitability.

To find out more about the benefits of additive manufacturing for design and production, visit Stratasys resellers, Pixel Sistemas, Stand B-33, Pavilion 4 and Comher, Stand C-18, Pavilion 2 from 28th May-1st June at BIEMH, Bilbao Exhibition Center.

Leave A Comment